Mcinnes Rolled Rings Erie has long been synonymous with precision engineering and high-quality rolled rings, serving industries ranging from aerospace to energy. With decades of expertise in crafting seamless rolled rings, Mcinnes has earned a reputation for delivering durable and reliable components tailored to meet the most demanding industrial needs. Whether you're a business owner, an engineer, or simply someone curious about advanced manufacturing, Mcinnes Rolled Rings Erie offers a fascinating glimpse into the world of metallurgy and industrial innovation. Their products are not just components but essential building blocks for machinery and equipment that power modern industries.

Located in Erie, Pennsylvania, Mcinnes Rolled Rings has become a cornerstone of the region's manufacturing sector. The company's state-of-the-art facility is equipped with cutting-edge technology that ensures every rolled ring meets stringent quality standards. From custom designs to large-scale production runs, Mcinnes Rolled Rings Erie has the capability to handle projects of all sizes. Their commitment to excellence and customer satisfaction has made them a trusted partner for businesses across the globe.

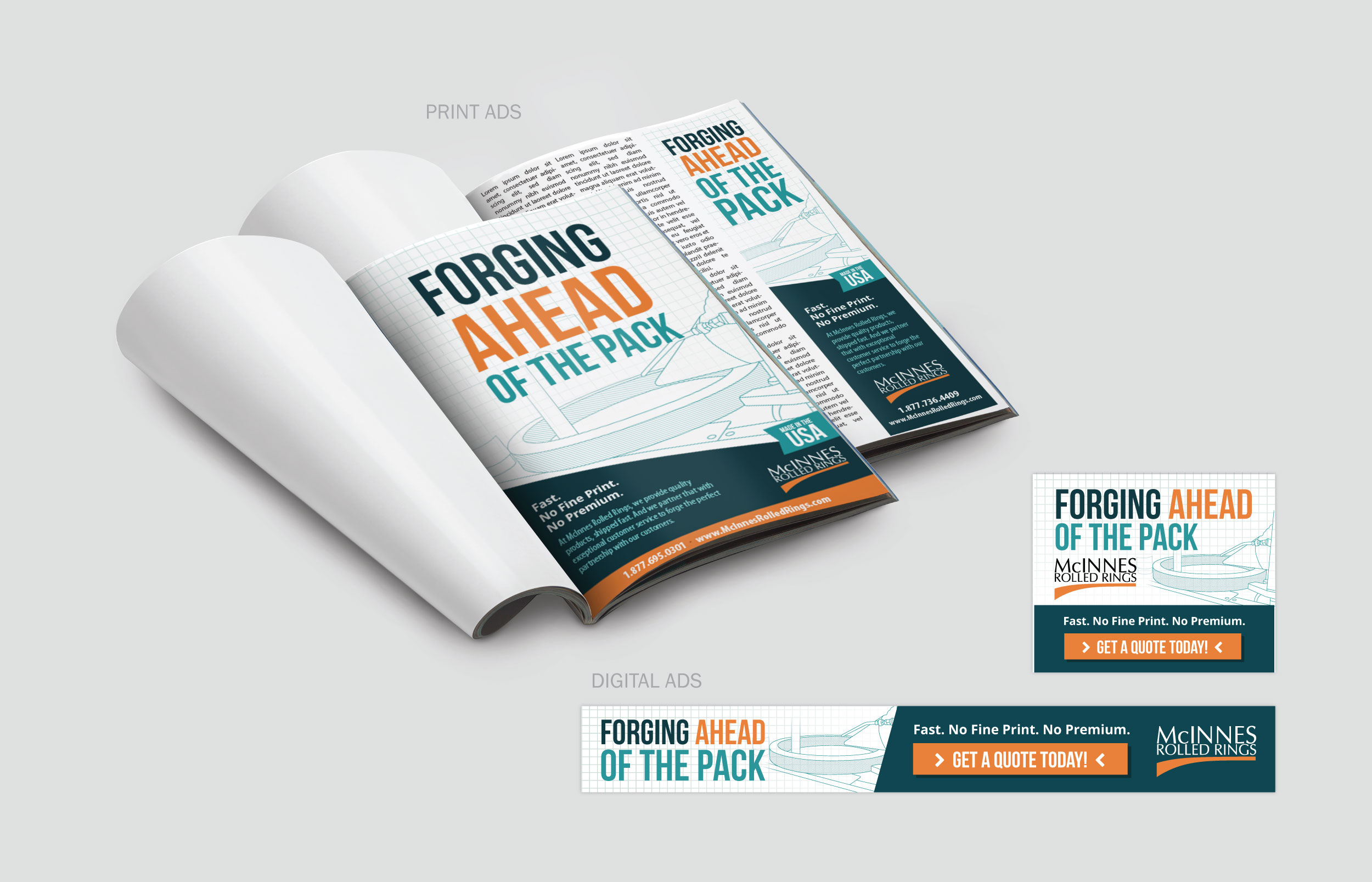

But what makes Mcinnes Rolled Rings Erie stand out in a competitive market? The answer lies in their dedication to innovation, sustainability, and precision. By leveraging advanced manufacturing techniques and adhering to rigorous quality control processes, Mcinnes ensures that every rolled ring not only meets but exceeds industry expectations. Whether you're looking for a specific alloy or need a custom solution, Mcinnes Rolled Rings Erie is your go-to partner for all things rolled rings.

Read also:Unveiling The Extraordinary Spoiled By Eight Uncles An Online Literary Feast

Table of Contents

- What Are Rolled Rings?

- Why Choose Mcinnes Rolled Rings Erie?

- How Are Rolled Rings Manufactured?

- What Industries Rely on Rolled Rings?

- Custom Solutions at Mcinnes Rolled Rings Erie

- Is Mcinnes Rolled Rings Erie Sustainable?

- How to Get Started with Mcinnes?

- Common Questions About Rolled Rings

- The Future of Rolled Rings in Erie

- Why Quality Matters in Rolled Rings

What Are Rolled Rings?

Rolled rings are circular metal components that are manufactured using a specialized rolling process. This process involves shaping heated metal into a ring shape, which is then cooled and machined to precise specifications. Rolled rings are known for their strength, durability, and ability to withstand extreme conditions, making them ideal for use in heavy machinery and equipment. They are commonly used in industries such as aerospace, automotive, energy, and defense.

Why Choose Mcinnes Rolled Rings Erie?

When it comes to selecting a rolled rings manufacturer, Mcinnes Rolled Rings Erie stands out for several reasons. First and foremost, their commitment to quality is unparalleled. Every rolled ring produced at their Erie facility undergoes rigorous testing and inspection to ensure it meets the highest standards. Additionally, Mcinnes offers a wide range of materials and alloys, allowing customers to choose the perfect option for their specific application.

- Decades of experience in rolled rings manufacturing

- State-of-the-art facility in Erie, Pennsylvania

- Custom solutions tailored to your needs

How Are Rolled Rings Manufactured?

The manufacturing process for rolled rings involves several key steps. First, a metal billet is heated to a specific temperature to make it malleable. The heated billet is then placed into a ring rolling mill, where it is shaped into a ring using specialized rollers. Once the desired shape and size are achieved, the ring is cooled and machined to precise tolerances. This process ensures that the final product is both strong and lightweight, making it ideal for demanding applications.

What Industries Rely on Rolled Rings?

Rolled rings are essential components in a wide range of industries. For example, in the aerospace sector, they are used in jet engines and landing gear systems. In the energy industry, rolled rings are critical for wind turbines and oil drilling equipment. The automotive sector relies on them for transmission systems, while the defense industry uses them in military vehicles and weaponry. Mcinnes Rolled Rings Erie has the expertise to serve all these industries and more.

Custom Solutions at Mcinnes Rolled Rings Erie

One of the standout features of Mcinnes Rolled Rings Erie is their ability to provide custom solutions. Whether you need a specific alloy, size, or design, Mcinnes has the capability to meet your requirements. Their team of engineers works closely with customers to understand their needs and deliver products that exceed expectations. This level of customization sets Mcinnes apart from other rolled rings manufacturers.

Is Mcinnes Rolled Rings Erie Sustainable?

Sustainability is a growing concern in the manufacturing industry, and Mcinnes Rolled Rings Erie is committed to reducing its environmental impact. They achieve this by using energy-efficient equipment, recycling scrap metal, and implementing waste reduction strategies. By choosing Mcinnes, customers can be confident that they are supporting a company that prioritizes environmental responsibility.

Read also:Kyle Maclachlan And Linda Evangelista A Timeless Fashion Romance

How to Get Started with Mcinnes?

Getting started with Mcinnes Rolled Rings Erie is a straightforward process. Begin by reaching out to their team to discuss your specific needs. They will guide you through the selection of materials, design options, and production timelines. Once the details are finalized, Mcinnes will manufacture your rolled rings with precision and deliver them on time. Their customer service team is always available to answer questions and provide support throughout the process.

Common Questions About Rolled Rings

Here are some frequently asked questions about rolled rings and Mcinnes Rolled Rings Erie:

- What materials are used in rolled rings?

- How long does it take to manufacture a rolled ring?

- Can Mcinnes Rolled Rings Erie handle large orders?

The Future of Rolled Rings in Erie

As technology continues to advance, the future of rolled rings manufacturing looks promising. Mcinnes Rolled Rings Erie is at the forefront of this evolution, investing in new technologies and processes to stay ahead of the curve. Their focus on innovation ensures that they will continue to be a leader in the industry for years to come.

Why Quality Matters in Rolled Rings

Quality is the cornerstone of Mcinnes Rolled Rings Erie's success. In industries where safety and reliability are paramount, there is no room for error. Mcinnes understands this and has built its reputation on delivering products that meet the highest standards. By choosing Mcinnes Rolled Rings Erie, customers can trust that they are receiving components that will perform flawlessly in even the most challenging environments.

In conclusion, Mcinnes Rolled Rings Erie is more than just a manufacturer; it is a partner that businesses can rely on for high-quality rolled rings. Their expertise, commitment to sustainability, and dedication to customer satisfaction make them a standout choice in the industry. Whether you're looking for standard components or custom solutions, Mcinnes Rolled Rings Erie has the capability to meet your needs and exceed your expectations.